Rajesh Rajgor interacted with Sunil Laroiya, President, Jamna Auto Industries Ltd., during Auto Expo Component 2023 and learnt about the company’s product line, innovative approaches and strategy for long-term growth

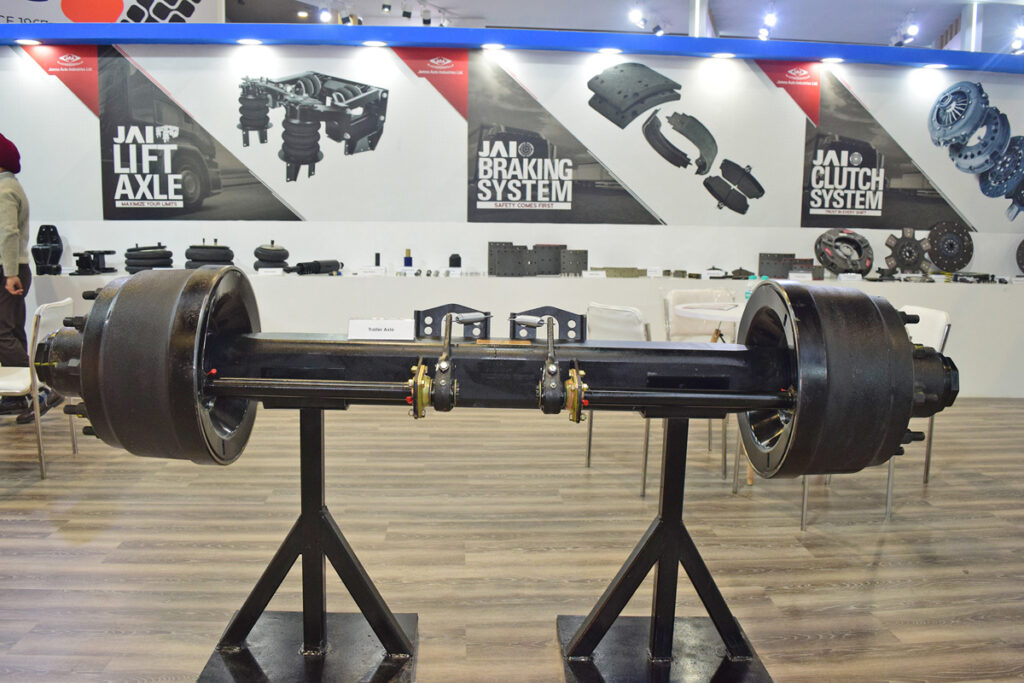

At the recently concluded Auto Expo Component 2023 trade show, Jamna Auto Industries (JAI), a manufacturer of conventional leaf springs, focused on showcasing upgraded versions of its products, boasting features like weight reduction, ride comfort and longer life span. Sunil Laroiya, President, Jamna Auto Industries, said: “Our focus was to showcase our innovation and new processes that lead to newer products. We have converted many of our conventional springs into parabolic springs. The major advantages of parabolic springs include weight reduction, ride comfort and longer life span. Additionally, we are focusing more on aftermarket products too. We are supplying leaf springs to OEMs as well to the aftermarket and have now introduced lift axles, clutch plates as well as brake pads.”

Recognising the Consumers’ Pulse

As India improves its infrastructure and builds state roads and national highways, fleet operators would need efficient vehicles with lower downtime and faster turnaround time. The move to parabolic springs ensures that vehicle maintenance is kept low. It brings the number of leaves from 12-13 to just three. “Instead of 13 leaves we have only three leaves in the spring and so maintenance comes down – that’s one aspect of recognising the needs of the market. Secondly, we have recently introduced air suspensions in trailers, bringing down the maintenance cost of trailer suspension to a negligible amount as compared to traditional multi-leaf spring suspensions,” Laroiya said.

“The feedback on air suspension has been extremely positive,” he added. Additionally, the company has paid attention to maximising the load-carrying capacity for trailers to 55 tonnes and improving load distributions with lift axles. “We have introduced a new suspension where we will have two axles on a mechanical suspension and one axle on an air suspension so that the customer can carry 54 tonnes. So, at the cost of mechanical suspension a customer can carry close to 54 tonnes, which is the unique feature of air suspension. Another benefit is that it can be lifted i.e. one of the axles on air suspension can be lifted if the cargo weight is less,” Laroiya informed.

What this implies is that the driver can run the trailer on two axles, thereby saving on four tyres. “That’s the one of the unique features we have given to air suspensions,” Laroiya stated. When asked about bus air suspension, he said the volumes were pretty less as of today and it may take another 3-4 years before we see a major conversion from mechanical suspension to air suspension. “We are ready and we have already developed major air suspension in our portfolio,” he added. In short, the company believes that it is only innovation and technological upgrades that will help make vehicles cost-efficient and improve the overall operations.

Optimising Resources for Growth

JAI has eight manufacturing facilities of which three manufacture air suspension and lift axles. “Our Pune plant along with manufacturing air suspension and lift axles also hosts a research and development where we have about 35 engineers. There is a separate plant for leaf springs in Chennai and in Pant Nagar which is a combination of leaf springs and air suspension,” Laroiya informed. In order to flow effortlessly in the automotive industry which is cyclical in nature, JAI invests a lot of efforts in the aftermarket not only India but on foreign shores too.

Even though the last two years proved to be tough for most players catering to OEMs, JAI maintained its bottom-line same as the good years. By offering highly developed items to the aftermarket, which is still largely unstructured today, JAI has actually taken a calculated risk. “We have done a lot of cost reduction in our entire supply chain system. We have closed some of our warehouses and are using our plants as warehouses. All this has helped us to maintain our bottom-line even if there is a major hit to our top-line. I believe 2024 should be as good as 2018-19 in 2024. With major changes seeping into the logistics sector and fleet owners looking at upgrading their vehicles, the opportunities are on the increase,” he said.