For automotive component manufacturers, securing a reliable lubricant for prolonged service and varying temperatures is crucial. There is a growing need for superior wear protection, pressure absorption, and resistance to water and corrosion. Traditional lubricants often fail to meet these rising demands.

Innovative Automotive Grease: Klübersynth LEB 94-81 BH – Made in India, engineered with German precision, thriving at temperatures even as low as -40°C

Klüber Lubrication has introduced Klübersynth LEB 94-81 BH, a lithium-free, high-performance, cost-effective solution for Indian automotive applications. This specialized lubricant reflects the company’s commitment to excellence and precision in addressing the unique needs of the automotive sector.

Limitations of Conventional Grease in Automotive Applications

- Limited Temperature Range: Traditional greases struggle with extreme temperatures, leading to degradation and reduced lubrication efficiency in both high and low-temperature conditions.

- Poor Water and Contaminant Resistance: Conventional grease may not effectively repel water or resist contamination, leading to corrosion and increased wear on automotive components.

- Increased Maintenance Requirements: Regular and frequent reapplication of grease is necessary for continued protection, adding to excess lubricant consumption, maintenance costs, and downtime.

- Environmental Impact: Traditional grease formulations may contain harmful additives, posing risks to the environment if improperly disposed of.

The Optimal Solution: Klübersynth LEB 94-81 BH

Klübersynth LEB 94-81 BH is designed to ensure reliable component performance, even in challenging environments. This innovation translates to heightened satisfaction levels and provides a competitive edge in the market.

Benefits for automotive applications

- Meets performance criteria till the end of life of the component through exceptional wear protection.

- Reduces maintenance needs with superior lubrication properties.

- Ensures reliable performance under diverse conditions due to its versatility.

A portfolio of groundbreaking advantages

In the realm of industrial machinery, the performance and longevity of components are paramount. Klübersynth LEB 94-81 BH represents a new era in lubrication technology, promising unparalleled benefits across various sectors.

- Exceptional Low-Temperature Performance: Engineered to defy extreme cold, it ensures uninterrupted machinery performance, setting new standards for reliability in any weather.

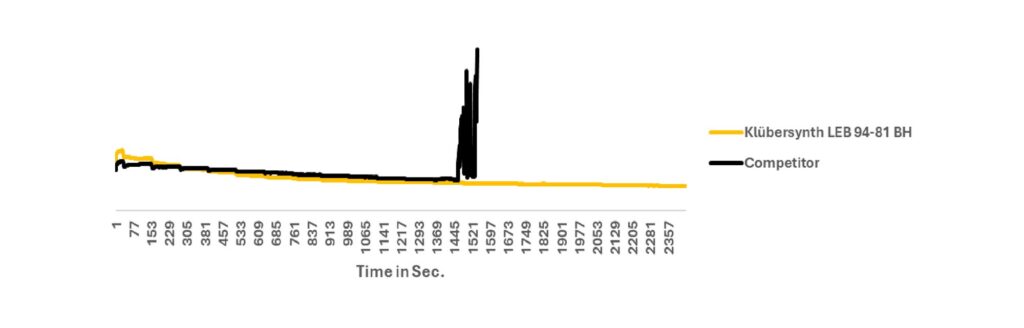

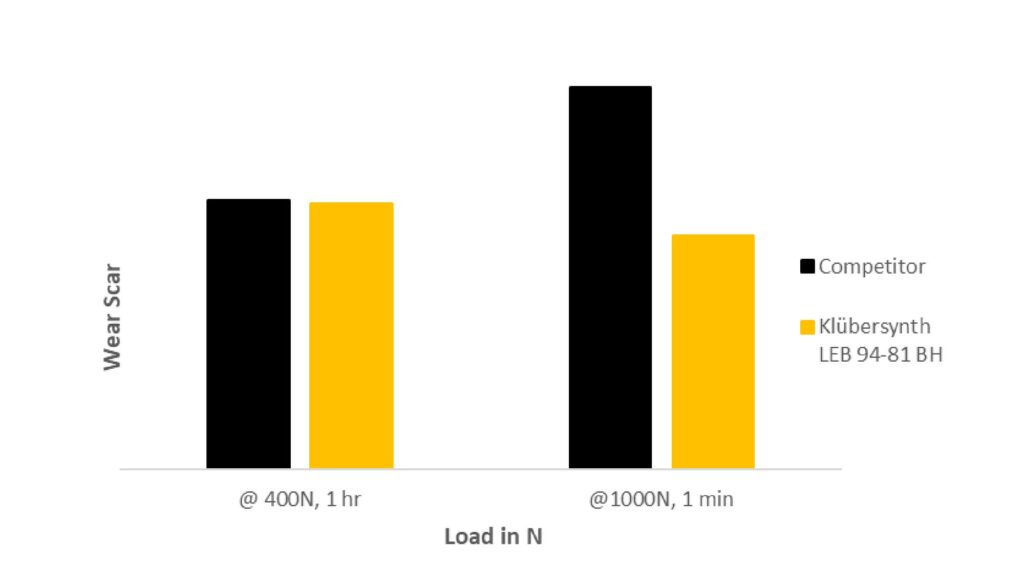

- Superior Wear Protection: High-quality lubrication enhances the durability and reliability of machinery, minimizing maintenance costs and maximizing operational efficiency. Reduced friction and wear ensure optimal performance over extended periods.

- High-Pressure Absorption: Designed to excel under extreme pressure, the lubricant ensures machinery operates seamlessly, maximizing productivity and efficiency.

- Excellent Water Resistance: Its water-resistant properties safeguard equipment against rust and corrosion, extending the lifespan of components and ensuring consistent reliability.

- Strong Adhesion: Superior adhesion ensures seamless machinery operations, providing unrivalled performance and peace of mind.

- Free of Heavy Metals and Chlorine: The formulation excludes heavy metals and chlorine, prioritizing environmental safety and compatibility with modern components. This focus on sustainability promotes responsible lubrication for a greener future.

Application Possibilities

Klübersynth LEB 94-81 BH is engineered for optimal performance under high-load conditions. It addresses friction points in plastic/plastic, plastic/metal, and metal/metal interfaces, ensuring enduring lubrication. Its functionality extends beyond conventional limits, delivering reliable performance in joints, guide rails, and gears. The lubricant is tailored for automotive applications, excelling in interior components, gear-shifting mechanisms, and CV joints. As a definitive NVH (Noise, Vibration, Harshness) solution for automotive interiors, it undergoes rigorous compatibility testing across a range of plastics and elastomers.