US-based automotive supplier Inteva Products LLC is set to expand its manufacturing facility in Chakan, Pune, with an investment of USD 3.3 million. This strategic move aims to boost production capabilities, meet increasing demand for automotive components, and create local employment opportunities. Rajesh Rajgor, who attended the announcement, shares insights into this expansion’s significance for both Inteva and the Indian automotive industry.

Scaling Up Production for Indian and Global Markets

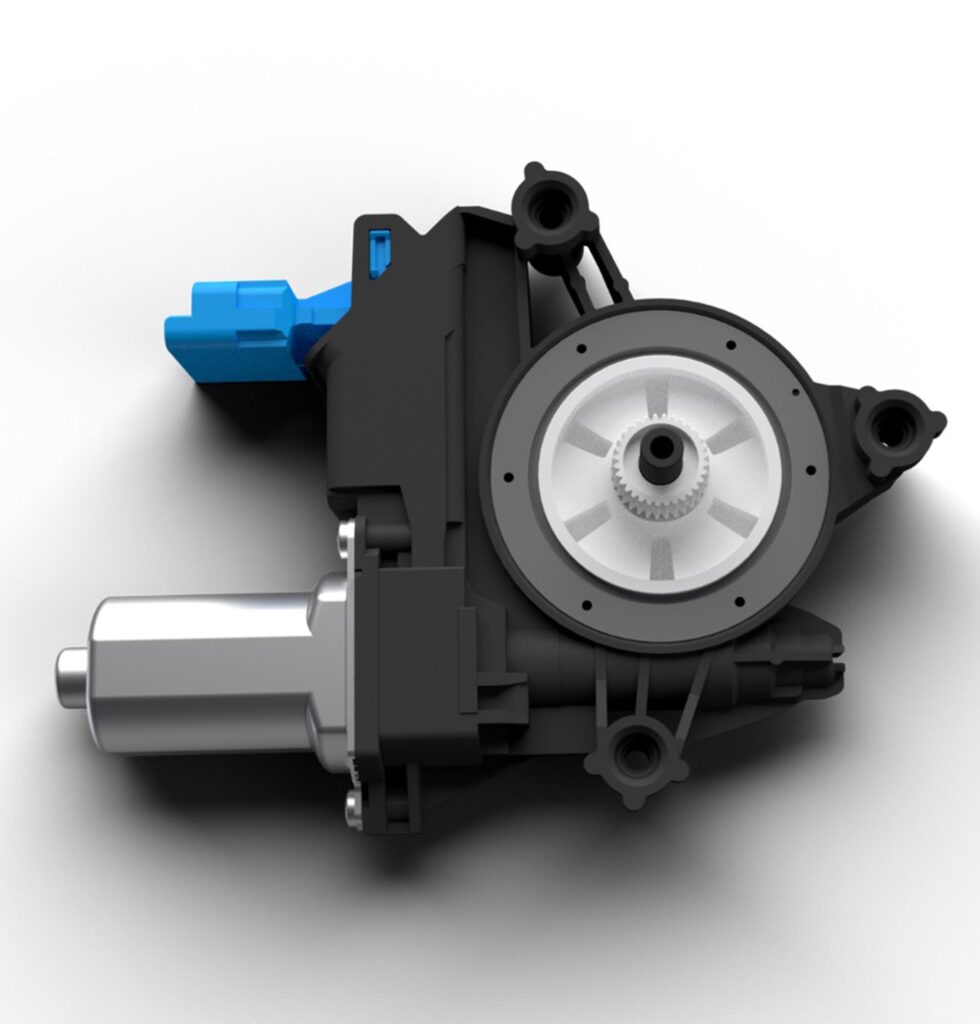

“Inteva Products is committed to enhancing its operational footprint in India,” said Gerard Roose, President and CEO of Inteva Products. The Chakan facility, Inteva’s only manufacturing plant in India, manufactures critical automotive components such as side door latches, liftgate latches, window regulators, and motors for window regulators.

With the addition of five new assembly lines, the facility will house a total of 17 production lines. This expansion will elevate the plant’s capacity to produce 6.3 million window regulators annually by the end of 2025, while motor production is projected to reach 9.6 million units by mid-2025. According to Sanjay Kataria, Vice President and Managing Director of Inteva India, this growth positions the company to better meet customer needs while maintaining its high standards for quality and efficiency.

Strengthening Relationships with OEMs

The Chakan facility supplies automotive components to leading OEMs, including Mahindra & Mahindra, Tata Motors, Stellantis, Hyundai, MG Motors, Volkswagen, and Force Motors. Additionally, it plays a crucial role in exporting window regulator motors to markets in South Africa and North America.

“Our investment reflects our commitment to innovation, localization, and delivering high-quality components,” Kataria emphasized. The expansion is expected to generate approximately 100 new jobs, furthering Maharashtra’s economic development and fostering local community growth.

As India’s commercial vehicle market grows, Inteva is exploring potential collaborations with truck and bus manufacturers. With freight transportation costs a major challenge for logistics, the company sees opportunities to provide innovative solutions for efficiency and sustainability.

“The rise of electric vehicles (EVs) and a push for greener transportation open up exciting possibilities for Inteva to partner with OEMs in the commercial vehicle segment,” Kataria explained. Advanced technologies developed by Inteva can help improve vehicle performance while ensuring compliance with regulatory standards.

Technical Expertise Driving Innovation

Inteva’s operations in India are bolstered by a technical center in Bengaluru, employing 320 professionals, including 181 engineers. This center provides cutting-edge support for product development and engineering across domestic and global markets.

“The technical center enables us to harness local talent and address specific market needs with innovative solutions,” Kataria noted. This synergy between manufacturing and R&D allows Inteva to remain agile and competitive in a fast-evolving industry.

A Decade of Excellence in India

Since commencing operations in Pune in 2008 and establishing its greenfield Chakan plant in 2012, Inteva has consistently delivered high-tech automotive solutions for both local and global markets. The current expansion is a testament to its commitment to India’s automotive sector and its long-term vision of sustainable growth. “As we continue our journey of growth and innovation in India, we remain poised to achieve greater success,” Roose concluded.

The expansion of Inteva’s Pune facility signals a significant step in meeting rising production demands. With a focus on advanced manufacturing, job creation, and exploring new markets, Inteva is poised to strengthen its role in India’s automotive landscape while contributing to the global automotive ecosystem.