Klüber Lubrication, a global leader in specialty lubricants, has built a formidable presence in India over the last 25 years. Under the leadership of Hitendra Bhargava, CEO & Regional Management Board Member – Asia Pacific, the company continues to deepen its footprint in India through strategic investments, sustainability leadership, and innovation tailored to both domestic and global market needs. In this interaction with N. Balasubramanian, Bhargava shares insights on Klüber’s growth journey, its alignment with the ‘Make in India’ initiative, sustainability roadmap, and how the company is addressing evolving industry challenges, particularly in the automotive and electric mobility sectors.

How do you see the growth of Klüber in India over the years in terms of manufacturing footprint, product offerings, end-user industries, sales growth, etc.?

Klüber Lubrication has built a strong legacy in India over the past 25 years, consistently delivering high-performance lubrication solutions across diverse sectors. Our sustained commitment to the market is reflected in our continued investments in infrastructure, innovation, and human capital.

To further reinforce our presence, we are making a strategic investment of ₹141 crores in our Mysore facility. This expansion will significantly boost our manufacturing and R&D capabilities, enabling the production of technologically advanced lubricants tailored for a broad range of applications. The upgraded facility will carry IATF and food-grade certifications, aligning with global quality and compliance standards. By investing in talent and infrastructure, we are cementing our leadership in specialty lubrication while actively contributing to India’s industrial growth.

Can you elaborate on Klüber Lubrication’s sustainability efforts?

At Klüber Lubrication, sustainability goes beyond minimizing environmental impact—it’s about creating positive, measurable change for industries worldwide. We adopt a two-pronged strategy: reducing our environmental footprint while expanding our positive handprint through the benefits we offer to customers.

We continuously work to reduce carbon emissions, improve resource efficiency, and integrate responsible manufacturing practices. This includes using environmentally compliant raw materials, minimizing production waste, and deploying energy-efficient processes across our operations.

Simultaneously, we help our customers achieve their ESG goals by offering lubricants that reduce friction, lower energy consumption, extend equipment life, and minimize maintenance. These benefits contribute significantly to operational efficiency and environmental performance.

Our leadership in sustainability was reaffirmed in 2025 when we received the EcoVadis Gold Medal, placing us among the top 3% of companies globally in terms of environmental and social responsibility. By following this dual approach, Klüber Lubrication is not only reducing its own impact but also enabling greener operations across a broad spectrum of industries.

How is Klüber contributing to the ‘Make in India’ initiative and strengthening local manufacturing capabilities?

Klüber Lubrication is deeply aligned with the ‘Make in India’ vision. A substantial portion of our product portfolio is now manufactured locally. In addition to localising global solutions, we have developed over 100 new products specifically designed for Indian customers.

What’s particularly gratifying is that several of these India-developed solutions are now being adopted in global markets—underscoring our R&D capabilities and India’s growing importance as an innovation hub. Our Indian R&D centre has evolved into a global competency centre for key application areas.

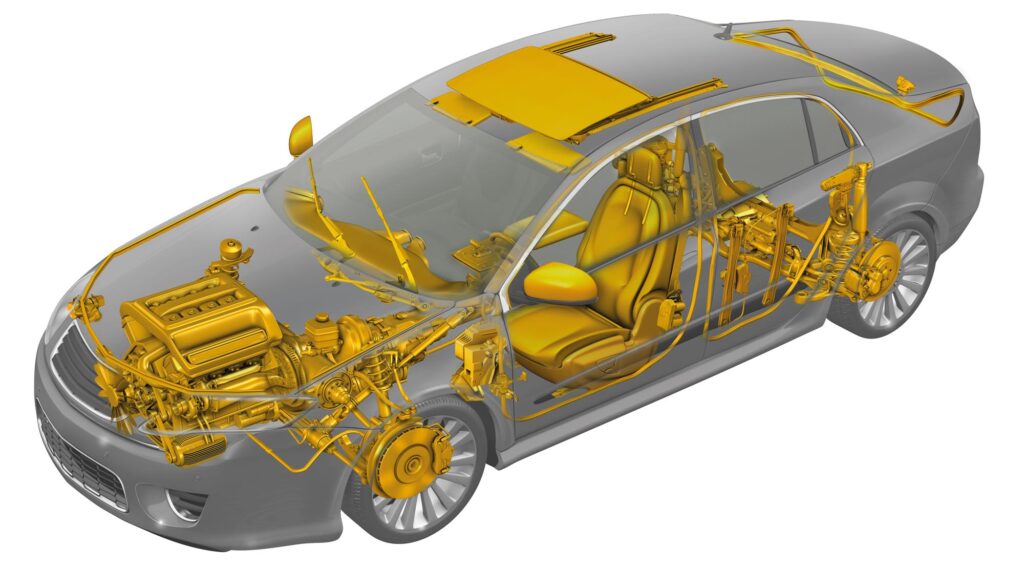

We blend German technology with local expertise, ensuring our solutions are tailor-made for Indian OEMs. A good example is our recently launched Klübersynth LEB 94-81 NH—a cutting-edge lubricant for the automotive sector that delivers high load-carrying capacity, low torque, and exceptional low-temperature performance. This is how we combine global standards with local requirements to empower Indian industry.

What challenges do industries face with commodity lubricants, and how does Klüber address these? Additionally, how are you meeting the evolving needs of sectors like EVs where demands are more specialised?

Commodity lubricants often fall short when it comes to optimizing performance, design flexibility, or cost-efficiency. Klüber Lubrication helps bridge this gap by educating customers on the long-term value of specialty lubricants.

There’s a growing shift in mindset—especially in India—where customers are no longer looking only for the cheapest solution, but for the most value-driven one. As in the automotive sector, the most successful vehicles are those offering better performance and efficiency, not necessarily the lowest price. The same principle applies to lubrication—high-performance lubricants reduce maintenance, extend equipment life, and improve energy efficiency, thereby delivering a compelling ROI.

In evolving sectors like EVs, we are constantly innovating to meet new challenges. EVs require lubricants with lower torque, higher wear resistance, and low-noise performance. These factors are crucial to extend battery range, enhance durability, and improve the driving experience. Our advanced NVH (Noise, Vibration, and Harshness) solutions are specifically developed to meet these emerging requirements, ensuring quiet, efficient, and high-performance operation.

We remain ahead of the curve by anticipating these needs and delivering application-specific solutions that support next-generation design and engineering.

What are the key challenges facing the manufacturing sector today and how is Klüber helping to address them?

Today’s manufacturers are under pressure to enhance efficiency, embrace sustainability, and adopt digitalisation—all simultaneously. Klüber Lubrication plays a crucial role in enabling this transformation.

A major challenge is improving performance while reducing energy consumption. Our advanced lubricants are designed to reduce friction, dampen noise, prevent corrosion, and extend operating life—allowing manufacturers to increase system efficiency and reduce downtime.

On the sustainability front, our track record speaks for itself. We’ve reduced Scope 1 and Scope 2 emissions by more than 78% since our 2019 baseline. We were recently awarded ‘Leader’ status in the ‘Carbon Management Level’ category by EcoVadis in 2024. Beyond our own footprint, we help customers reduce their Scope 3 emissions by offering carbon transparency data for our products, helping them make more informed, sustainable choices.

In terms of digitalisation, we provide smart lubrication solutions that enable real-time monitoring and predictive maintenance, helping customers avoid costly downtime and optimise operational planning.

How are you meeting the evolving needs of the Indian auto industry?

Two major trends are shaping the Indian automotive landscape—the surge in SUV demand and the rapid rise of electric vehicles. Each trend comes with unique lubrication challenges.

SUVs demand higher load-carrying capacity and enhanced comfort levels. Our lubricants meet these needs with superior performance under high loads, while also addressing safety and environmental concerns such as emissions and odour control.

In EVs, range anxiety remains a key challenge, largely driven by the current charging infrastructure. Our high-performance lubricants enhance the efficiency of critical EV components such as bearings and gearboxes, thereby improving energy utilisation and extending vehicle range. Additionally, our low-noise greases address the growing NVH requirements in EVs, where even minor noises can affect perceived quality.

We’re committed to supporting OEMs and Tier 1s with lubrication solutions that meet the performance, efficiency, and sustainability goals of tomorrow’s mobility.

Beyond auto, which other industries present significant opportunities for Klüber in India?

While automotive remains a major focus, Klüber Lubrication has built strong relevance across various industrial segments. These include cement, steel, power, food & beverages, pharmaceuticals, bearing manufacturing, textile machinery, and wind energy, among others.

All these sectors face complex challenges related to wear, friction, energy loss, and maintenance. We offer highly customised, application-specific lubrication solutions to address these pain points, helping customers enhance performance, reduce downtime, and lower total cost of ownership.

As India’s industrial landscape evolves, Klüber is well-positioned to support this growth with world-class technology, local expertise, and a steadfast focus on performance, safety, and sustainability.