Green hydrogen stands as an essential element in achieving a climate-neutral world, applicable in sectors ranging from transportation and buildings to manufacturing. With its extensive involvement in fuel-cell technology development, Bosch is at the forefront, equipped for the hydrogen era. The company is actively engaged in the creation of technologies spanning hydrogen production, compression, storage, and application across the entire hydrogen value chain. During the Bosch Tech Day 2023, a glimpse into the company’s product and service portfolio is unveiled.

Highlighted Displays at Bosch Tech Day 2023

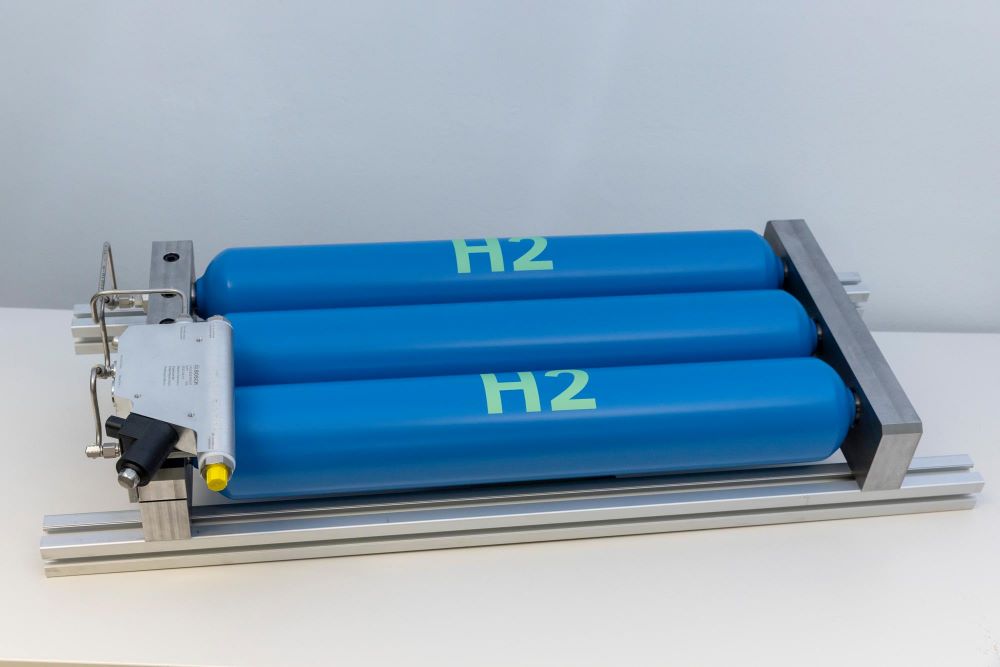

PEM Stack – Paving the Way for Climate-Neutral Transport

The PEM fuel-cell stack serves as the nucleus of the mobile fuel-cell system, with PEM signifying proton exchange membrane. Comprising numerous individual fuel cells, this stack generates electricity and water through the reaction between hydrogen and oxygen. Facilitated by the proton-conductive membrane, the fuel cell’s design averts the flow of electricity between the anode and cathode, while also preventing hydrogen from migrating to the oxygen side. The creation of the stack incorporates high-speed laser welding, a distinct Bosch innovation, ensuring 1,200 meters of welds per stack remain hydrogen-tight. These stacks are produced in Bosch facilities in Bamberg, Germany, and Wuxi, China, with additional manufacturing sites in the pipeline, including one in the United States.

Prolonging the Lifespan of PEM Fuel Cells – Counteracting Aging Effects

Fuel cells experience aging phenomena over their operational life, involving the oxidation and degradation of platinum particles and carbon supports, as well as the thinning of catalyst layers. To address this, Bosch researchers have devised a specialized coating to mitigate these processes. Strategic operational tactics circumvent aging-related stressors, ultimately extending the life of PEM fuel cells to potentially 30,000 operating hours. Furthermore, certain aging effects can even be reversed through innovative restorative procedures developed by Bosch researchers.

Hydrogen Engine – Proven Foundation with Carbon-Neutral Operation

Hydrogen’s utility extends beyond fuel cells to hydrogen engines, ideal for heavy-duty vehicles engaged in prolonged operations with substantial payloads. These engines leverage existing powertrain components for their structure, encompassing fuel, air supply, and exhaust systems. Bosch’s development efforts encompass two hydrogen engine systems: port and direct injection of hydrogen. The challenge lies in ensuring the reliability of the injector for direct injection over a truck’s service life, with the emitted nitrogen oxide, the sole significant waste product, effectively managed through exhaust-gas treatment systems.

IVECO Heavy Duty FCEV – Hydrogen-Powered Truck for European Markets

The IVECO Heavy Duty FCEV, powered by a hydrogen fuel cell-electric system, targets the European semi-truck market. This vehicle, combined with green hydrogen, boasts zero local emissions. With a hydrogen payload of approximately 70 kilograms, the truck achieves an 800-kilometer range before refueling, a process taking around 20 minutes. This capacity renders the IVECO Heavy Duty FCEV adaptable for various applications, including long-haul transport.

eDistance Truck – Bosch’s Contribution to Carbon-Neutral Trucking

Bosch offers diverse powertrain solutions for long-haul trucks, including fuel cell-electric, battery-electric, and hybrid options. Fuel-cell powertrains shine when dealing with heavy payloads and extended routes, combining short refueling times with extensive ranges. By utilizing renewable-source hydrogen, these operations become carbon-neutral. Bosch provides individual powertrain components as well as complete fuel-cell power modules, streamlining integration and fostering climate-conscious trucking.

Hydrogen Filling Stations – Enabling Hydrogen Compressed Refueling

Efficient and rapid refueling of hydrogen-powered vehicles hinges on compressing hydrogen to pressures of up to 900 bar. Bosch Rexroth’s compressors, marked by efficiency and low maintenance, play a pivotal role in establishing a functional hydrogen infrastructure. Collaborating with Maximator Hydrogen, Bosch Rexroth delivers an efficient compression solution for filling stations, storage tanks, and pipelines. By 2030, Maximator Hydrogen aims to produce around 4,000 compressor systems, backed by Bosch Rexroth’s energy-efficient operational approach. This initiative includes scalable drive units with up to 250 kilowatts, delivering a cost-effective gateway to hydrogen technology and potentially halving total ownership costs compared to available alternatives.

Additional Exhibits at the Event

Apart from the featured advancements, Bosch’s showcase encompasses a diverse range of exhibits:

- Stack and Smart Electrolysis Module – Elevating H2 Electrolyzers’ Capabilities

- Solid Oxide Fuel-Cell System – Meeting Demand for Flexible Power Generation

- Platinum Recycling from Fuel-Cell Stacks – Sustainable Resource Management

- Manufacturing and Testing Technology – Illuminating Fuel Cell Production Processes

- H2-Ready Industrial Boiler – Paving the Way for Climate-Neutral Heating and Process Heat

- H2-Ready Boilers – Versatile Climate-Friendly Heating Solutions