ZF continues to lead the charge towards developing innovative technologies to make commercial vehicles more sustainable. As the industry undergoes its greatest transformation since the invention of the internal combustion engine, ZF will continue to set the pace of innovation by actively responding to customer needs with a full-flex portfolio. The company will showcase as such during this year’s IAA Transportation in Hanover, Germany, from September 17th-22nd.

As the world’s largest component and system supplier with the broadest portfolio to the commercial vehicle industry, ZF is well positioned to provide the technical expertise, manufacturing flexibility and cross-divisional technology transfer needed to provide cost-effective solutions. ZF anticipates that customer demand for e-mobility to grow over the next few years.

Hybrid technologies

ZF is investing in hybrid drivetrain technologies as a rapid solution to reduce commercial vehicle emissions. ZF’s latest variant of its successful TraXon 2 transmission, the TraXon 2 Hybrid, is a new concept that effectively enables OEMs to incorporate hybrid technology into their existing design platforms with reduced effort and complexity. The system facilitates clean, safe and efficient mobility, while bringing total cost of ownership (TCO) benefits.

Hybrid technologies offer significant emissions reduction potential while retaining many of the advantages terms of range and refilling capabilities. With its extensive experience in developing hybrid technologies for passenger cars, ZF is able to leverage its technical and industrial capabilities to develop viable, cost-effective hybrid solutions.

Zero emissions technologies: ZF’s E-Mobility Kit

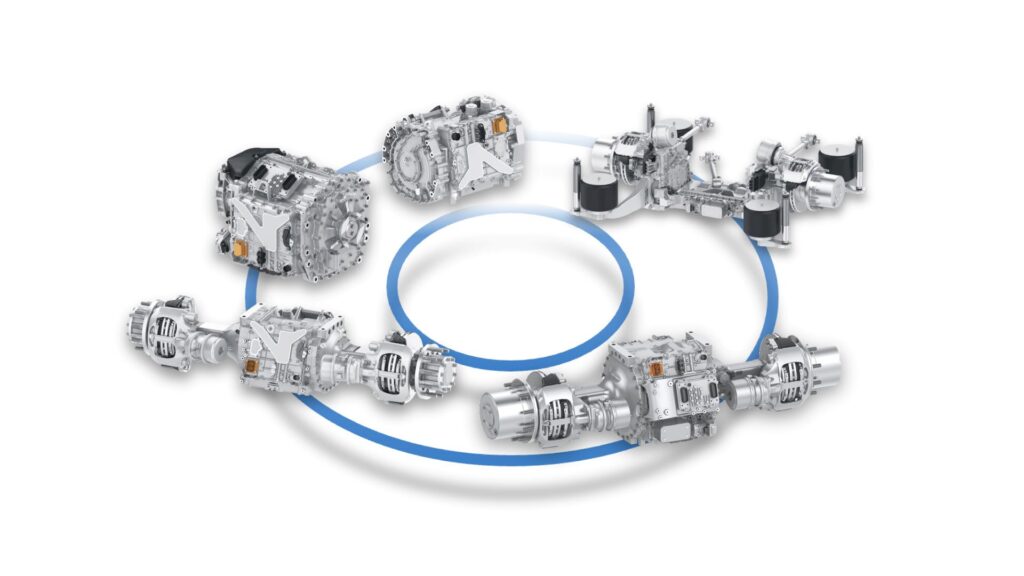

ZF’s family of next generation electric drives provides all the elements manufacturers need to electrify their vehicles. ZF’s E-Mobility Kit employs a unique modular approach, seamlessly integrating components to create a compact, lightweight and powerful system. ZF’s in-house development of key components, including inverters, e-motors, transmissions, e-actuators, and electronic control units including software, allows them to tailor e-drive solutions to the unique specifications of OEM customers across various vehicle applications.

Catering to a wide range of customer requirements, ZF’s kit includes a central drive platform – the CeTrax 2 dual and CeTrax 2 – which can slot into the same space as a conventional transmission, as well as an axle drive platform – the AxTrax 2 dual and AxTrax 2 – which sits closer to the wheels, providing greater design flexibility.

OEMs have the flexibility to use complete e-drive systems from ZF or integrate individual components, software, or subsystems. This versatility facilitates a smooth transition to electric mobility, offering electric drive solutions that can either be easily integrated into existing vehicle platforms or provide additional design flexibility to meet various applications.

Electrified Trailers

The trailer will play an increasingly significant role in helping to decarbonize road freight transport, whether hauled by an ICE or electric truck. ZF’s electric trailer concept, which integrates its in-house developed AxTrax 2 e-Axle together with its trailer EBS and battery system box into a trailer, effectively converts an ICE powered truck into a hybrid. In the case of an electric vehicle, the electric trailer concept effectively extends the vehicle’s range.

When pulled by an ICE, the technology can help reduce CO2 emissions by up to 16% through recuperation, while up to 40% with the plug-in-hybrid solution. The concept is possible thanks to the development of ZF’s latest electrified traction axle, the AxTrax 2, which was originally designed for trucks, buses and coaches. Integrating its e-mobility technologies such as the AxTrax 2 combined with ZF´s leading expertise in braking control systems demonstrates how ZF applies its technical-transfer capabilities to meet a wide range of applications effectively.

eWorX

ZF also excels in the domain of electrified power-take off solutions (ePTO). ZF’s eWorX integrates components including a 50-kW e-motor, inverter and electronic control unit with application-specific software. eWorX powers a range of equipment including hook lifters, skip loaders or loading cranes installed on electric commercial vehicles. Developed in close collaboration with OEMs and body manufacturers, the concept is proving highly successful with demand for eWorX products expected to double over the next few years.

ZF’s latest version of eWorX is integrated into the frame of the truck and uses the truck’s cooling system. The innovative design reduces installation space and allows the system to be used in a wider range of vehicle applications. Additionally, ZF will soon introduce a next generation to the ZF eWorX family with a 70 kW, 800 V, cyber security capable drive for electric power take-off solutions as well as a multifunctional, bidirectional I/O device to power applications on electrified commercial vehicles.