By Amritashu Bardhan and Madan Ramachandran

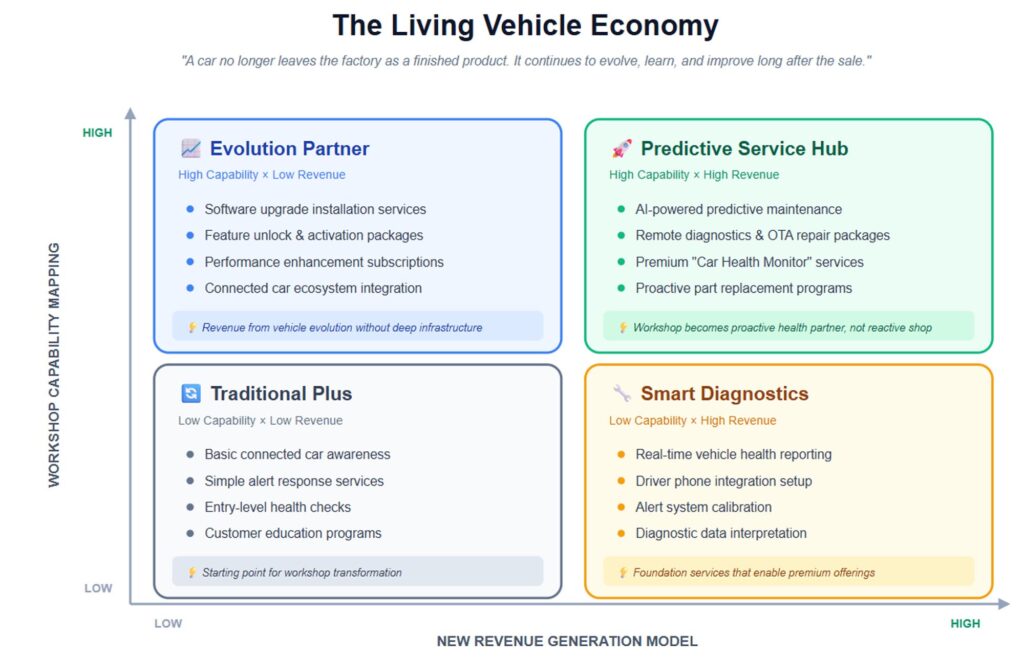

Cars can warn us before they break. If that is true, the workshop is no longer the last stop. It is part of the journey. The real question is whether they (the dealer, the independent, or both together) are prepared for this new paradigm and can turn early warnings into quick, fair fixes.

When the mechanical meets the digital

Twenty years ago, Madan and I walked through a crowded parts market in Delhi, India. It was a maze of used components, mechanics who could diagnose by sound, fabricators who’d build anything the OEM would charge a fortune for. We weren’t gear heads, but we understood something fundamental: most of a car’s life happens outside the dealership.

That pattern isn’t unique to India. In most markets, the center of gravity shifts to independent workshops after warranty; in markets such as India and the U.S., independents handle roughly 70% of post-warranty repairs. The logic is simple: a trusted local shop, practical prices, and fast turnaround. Now add a new layer. Cars carry computers, sensors, and permanent connections. They update like phones. They can ask for help before something fails.

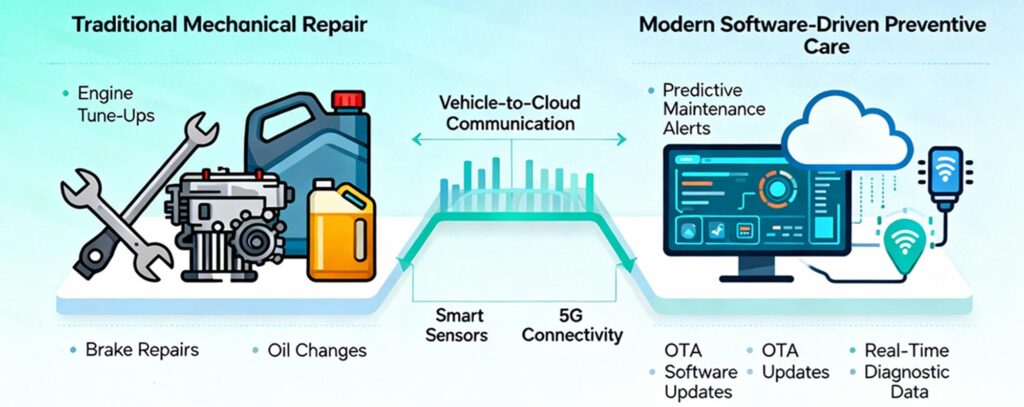

An independent garage or a dealer workshop with skilled mechanics has to deal with over-the-air updates and digital diagnosis. According to a McKinsey 2023 report, by 2030, more than 90% of the vehicles sold worldwide will be connected. So a mechanical noise could be a data point or a faulty code, a software update, or a cloud issue. The question is not who owns the service bay, but how we interpret signals along the car’s journey.

The aftermarket is no longer a parallel industry. It’s becoming an extension of the connected ecosystem. How we bridge mechanical expertise with digital intelligence will determine whether software-defined vehicles work beyond the warranty period. Navigating this transition requires understanding two paradigms.

From ownership to experience

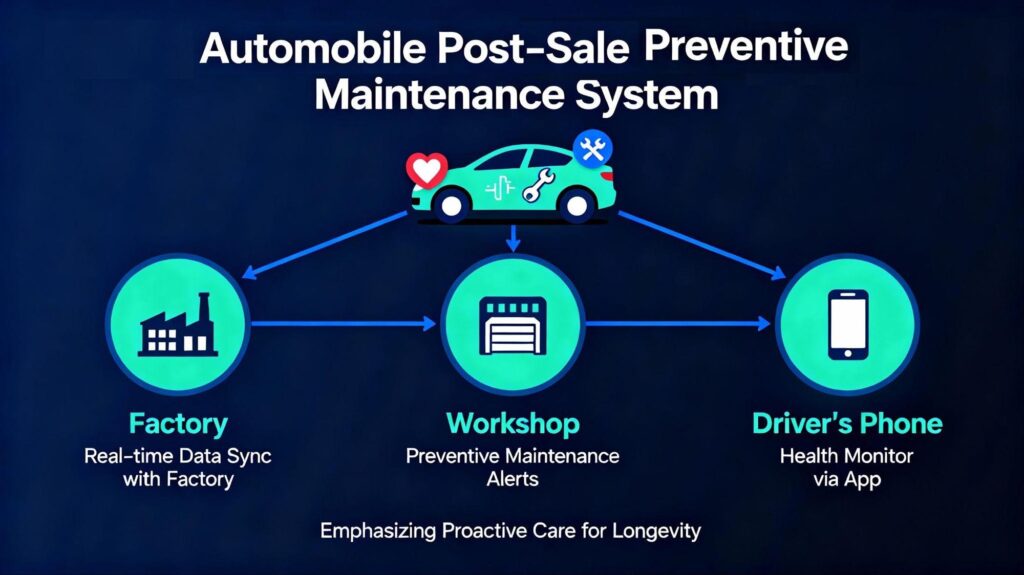

First, a car no longer leaves the factory as a finished product. It continues to evolve, learn, and improve long after the sale. If it can report its own health, who should see that first: the maker, the local workshop, or the driver’s phone, which acts as a personal health monitor for the car, alerting the owner to any potential issues? If all three see it together, do we still wait for a breakdown, or plan a short visit?

“Connectivity is turning repair from reacting to problems into preventing them.”

Prediction moves faster than habit. If software can forecast brake wear or filter life with decent accuracy, what should we do with that forecast? Should it become an offer the driver accepts with a tap? Should the workshop preload parts because the car booked itself? And if the prediction is wrong, who takes responsibility?

Trust is the cornerstone of this evolution. It’s not just about trusting a brand, but also about the confidence in the hand that turns the wrench and the tool that flashes the update.

Skills the workshop needs next

Second, skills matter most where the car meets the wrench. Parity is non-negotiable: dealer and independent technicians need equal command of the car’s software and electronics. The craft of a good mechanic endures, but it is widening into sensors, updates, and diagnostics, opening absolute paths for growth and learning. A modern fault can live in a sensor, a wire, a setting, or a cloud service. A technician might fix a rattle at 10 a.m. and a software rollback at noon.

What’s crucial is a shared language. Enough common ground that a local shop and a global manufacturer can look at the same dashboard and read it the same way. Enough access that a certified independent does not wait days for a code to unlock a module. Enough humility on all sides to say, “Let’s recheck the data.” This inclusivity is what will drive the industry forward.

Consider a simple case. A driver says, “My voice AI assistant stopped listening.” Is it a broken microphone, a privacy setting, or a tired network? The symptom walks in through the service door. The cause may sit in three places at once. Which shop can chase all three angles without sending the customer home twice?

“Tomorrow’s winners will own the experience, not the address.”

What good looks like

Picture this: Your car tells you, “brake pads will need replacement in about 60 days.” The message appears on your phone, in plain English. No warning lights at the last minute. No surprise breakdown. Your trusted local mechanic gets the same message with enough detail to order the right parts and prepare for the job. You get a text: “We can do this in two weeks, takes an hour, here’s the price.” You tap to book.

When you arrive, the mechanic replaces the pads and handles any software updates the brake system needs, all in one visit. You’re done in an hour because everything was ready. No callbacks because “we need dealer access to reset the sensors.” No second trip because “the computer needs updating separately.” Your independent shop handled it the same way the dealer would have, but faster and cheaper because they knew it was coming.

This simple scenario requires both shifts working together. The first shift, from a car as a static machine to a connected service, means your car can warn you early rather than leaving you stranded. A connected service is a proactive approach to vehicle maintenance in which the car communicates its health status and potential issues to the owner and the service provider. The second shift, equipping independent shops with digital tools and training, means you don’t lose your trusted mechanic just because cars got smarter. When both work, you get the best of both worlds: your vehicle looks after itself, and your mechanic can look after your car.

Closing

The lesson from that crowded market wasn’t nostalgia. It was respect for craft under constraint. Today, the craft needs connected know-how too. The workshop is still where the promise meets the pavement, and where trust is earned one visit at a time. So when a car whispers that it needs attention, who hears it first, who acts next, and how little friction does the driver feel along the way? That answer will decide loyalty more than any spec sheet. The shops that read the signals and fix fast—dealer or independent—will own the experience.

ABOUT THE AUTHORS

Amritashu Bardhan is an automotive leader with 20+ years across OEM and ancillary roles, now driving vehicle concept development at Maruti Suzuki India. He builds application-engineering capability, retools processes for zero-defect delivery, and ships programs on time. His work spans emerging-market chassis design and cross-cultural teams; he has published in SAE journals, given international talks, and filed multiple patent applications. He writes in his personal capacity.

Madan Ramachandran is a senior technology business leader with 20+ years of experience driving growth, scale, and transformation at SAP, Qlik, Salesforce, and Amazon Web Services. He focuses on translating vision into operating mechanisms, go-to-market strategies, and measurable outcomes for customers. He writes in his personal capacity